-

Rubber roller manufacturer polyurethane PU rollers supplying

There are several ways to maintain the printing rubber roller:

1. The rubber roller should be cleaned carefully after the production operation is completed every day, and washed twice;

2. Designated chemical agents, such as industrial alcohol, must be used to clean the printing rubber roller, and corrosive

solvents must not be used;

3. Take off the rubber roller during holidays to prevent deformation under pressure;

4. For the protection of the surface of the printing rubber roller, it should be wrapped in newsprint and placed in a ventilated and dark place. -

rubber polyurethane pu roller for machine parts

Characteristics of rubber polyurethane pu roller

Polyurethane rubber roller a very high mechanical strength and wear resistance, anti-aging and oil resistance is also very good, commonly used in papermaking, chemical fiber, wood processing, plastic processing machinery. -

Polyurethane PU rubber wheels with 6001model bearing

Characteristics of polyurethane materials

1. Good flexibility

2. Divided into solvent-resistant and abrasion-resistant varieties, each with better abrasion resistance and oil resistance

Good features

3. Good resistance to oxygen, ozone, and ultraviolet radiation

4. Not resistant to acid and alkali -

Hot stamping silicone rubber roller with High temperature resistance

Custom-produced all kinds of specification hot stamping silicone rubber roller

Material: high temperature resistant silicone material.No glue opening at high temperature.

The hardness of silica gel roller can be determined according to the specific application. The general specifications are 40A°, 50A°, 60A°, 70A°, 80A°, up to 90A°, and the maximum hardness of 90A° is generally used for high temperature bronzing rolls rollers. -

Laminator silicone rubber roller with shaft

Laminator rubber roller

Application: Cold laminating and laminating processing of various spray painting surfaces, advertising light box cloth, printed matter, photos, banners, certificates, certificates, pictures, etc.

Size:650,700,750,1350,1600

Model:230,260,320,330,350 -

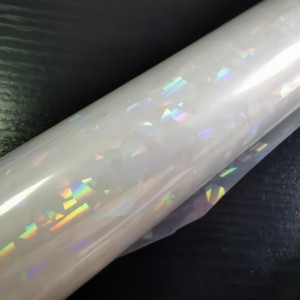

Toner Foil Roll Transparent Paper Stamping for Reactive Laser Print

toner foil features:

the best temperature for hot stamping is 95-135 degrees.

Please choose different models of hot stamping paper for trial hot stamping according to different stamping substrates and patterns.

-

High temperature resistant silicone material

High temperature resistant silicone material

Vulcanized silicone rubber is a new type of silicone elastic.Injection molding silica gel on rollers of printers, copiers, etc., rollers for tanning industries such as printing and dyeing, papermaking, printing, environmental protection, and plastics

-

Vulcanized silicone rubber material

All silicone rubber products need to be vulcanized because the silicone rubber has higher application value after vulcanization. The mechanical properties are greatly improved. It is insoluble in water and other characteristics in the solvent.

-

Hot Stamping Foil White Pigment Color for Cosmetics Plastic PP

High-end cosmetic bottles also need a bronzing film with an excellent printing effect.

We have special hot stamping films on PP, PET, PS, ABS and other plastics.

Especially for excellent cosmetics, like Dior, Clinique, MAC, L'Oreal etc

And the hot stamping foil can apply for paper and plastic, leather, textile.

-

Various types of industrial rubber rollers

Our rubber rollers are widely used in textile, printing and dyeing machinery (rolling roller, printing machine rubber roller, coating rubber roller, calender, setting machine rubber roller, mercerizing machine, etc.), paper making, Plastic printing, packaging, industrial, wood, glass, steel metallurgy, tobacco, transportation and other equipment -

Red Generic Foil Hot Stamping Foil For Plastic and Paper

1.Choosing appropriate hot stamping foil on different stamping products, then cut the hot stamping foil to appropriate length according to stamping area.

2.We have to control well the temperature, pressure and bronzing speed, the three respects should work in well, there are also differences between different bronzing products or materials when bronzing.

* General when the pressure heavy, the temperature should high, the bronzing speed should more quick in the course of bronzing. The recommended temperature is 115-125℃. -

Multi-color Hot Stamping Foil Printing for Leather

The hot stamping paper process uses the principle of heat and pressure transfer to transfer the aluminum layer in the anodized aluminum to the surface of the substrate to form a special metal effect.

FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Decai's bronzing, heat transfer silica gel roller and wheel, hot stamping silicone rubber plate(pad)are widely used in stationery, electrical appliances, toys, cosmetics boxes, cigarette packets, wine box wood, stainless steel, glass, paper, leather, soft and hard plastic printing packaging field.