FREE SHIPPING ON ALL BUSHNELL PRODUCTS

-

Product Description We off...

Plastic Injection Mold Labe...

-

Product details Heat tran...

Heat Transfer Printing Film...

-

In-mold label is mainly use...

Injection Molding In Mold L...

-

Feature: All kinds of plast...

Heat transfer films for pla...

-

Short description Factor...

60 Micron In-mold Sticker F...

-

Product Description 1.W...

Eco-Friendly In Mold Label ...

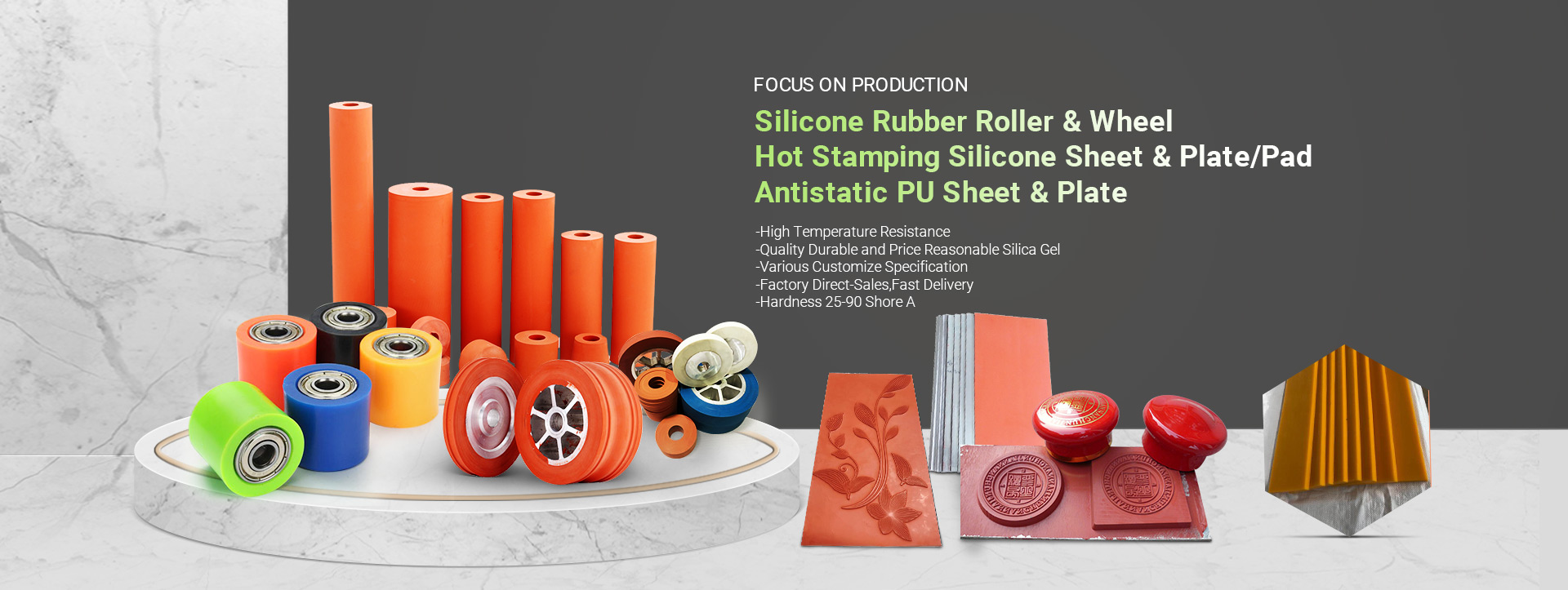

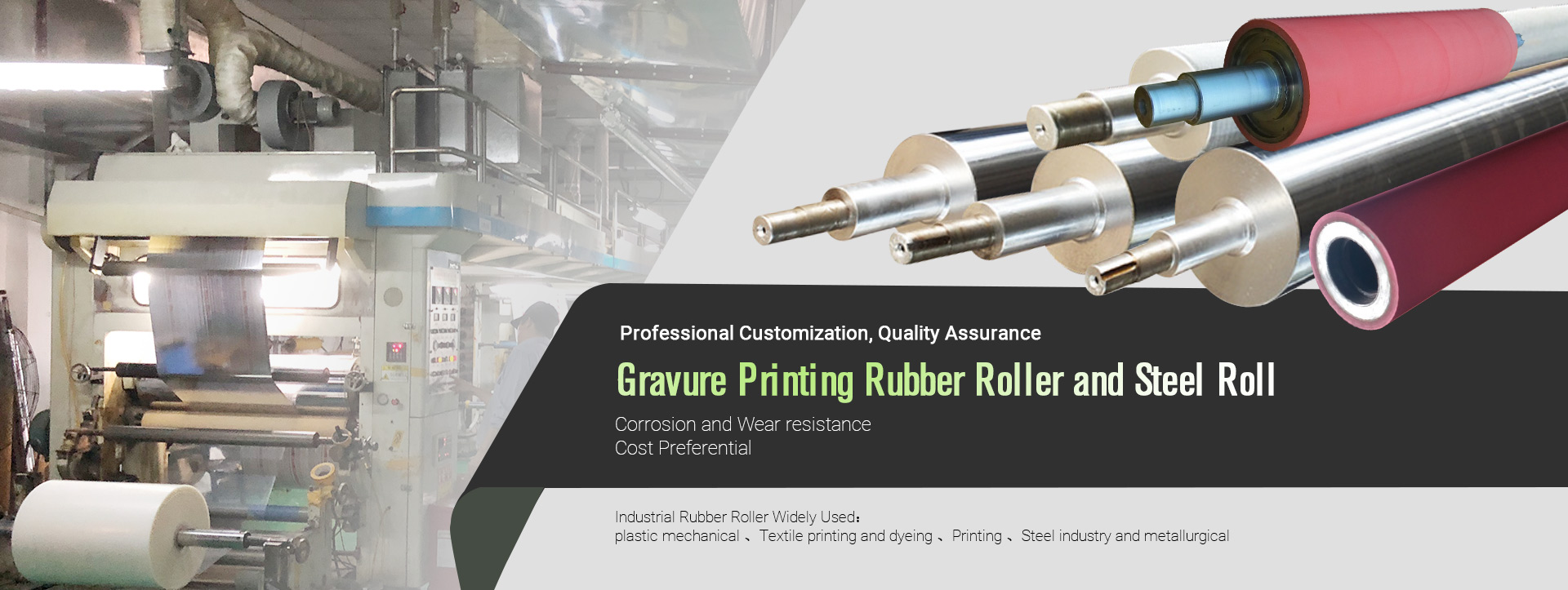

Decai New Material Co., Ltd. is a professional manufacturer of high-precision hot stamping silicone rubber roller and wheel, gravure printing rubber roller and various industrial rubber rollers.

explore our collections

optics for every moment

-

injection iml for pp cup co...

injection iml for pp cup container

-

Welcome to contact us—...

in mold labeling line production for ...

-

Welcome to contact us ...

18-100 thickness waterproof glossy in...

-

De cai honorise new materia...

factory heat transfer film for abs pl...

-

De cai honorise new materia...

pet thickened flower heat transfer fi...

-

City:Wezhou, Zhejiang W...

High quality paint bucket packaging s...