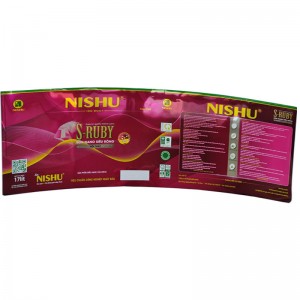

One of the biggest advantages of IML for plastic paint buckets is its aesthetic appeal. The labels are printed on a film that is inserted into the mold, which creates a seamless, high-quality label that is durable and attractive. This technology enables the manufacturers to produce buckets with vivid and vibrant colors, which attract customers and enhance brand value.

Moreover, IML technology ensures that the label is embedded into the bucket's surface, making it resistant to water, chemicals, and abrasions. This means that the label will not peel off or fade easily, ensuring the bucket remains good-looking for an extended period.

Another significant benefit of IML for plastic paint buckets is that it allows for flexibility in design. The technology enables the manufacturer to print intricate designs and patterns accurately, which helps differentiate their products from competitors. This means the manufacturers can customize their products according to their customers' preferences, enhancing customer satisfaction and loyalty.

Furthermore, IML technology for plastic paint buckets is environmentally friendly. The labels are made with eco-friendly materials, and the printing process is free of toxic chemicals and solvents. This helps manufacturers to reduce their carbon footprint significantly, promoting environmental sustainability.