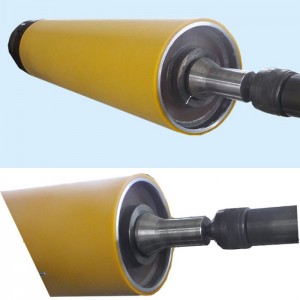

wholesales Carbon steel chromed mirror roller

1-Material: high quality 45# seamless steel pipe,stainless steel, alloy steel precision forging pipe;

2-Structure: Various flow channel or jacket design;

3-Processing: American 3M abrasive precision grinding, tempering by trap heat treatment process, multiple stress relief, quenching, Heef-25 high efficiency micro-crack hard chrome plating;

4-Accuracy: roughness Ra0.005 (level 14 or above), cooling or heating temperature difference≤±1℃, thermal deformation≤0.01mm. Straightness ≤0.005mm, runout ≤0.005mm, coaxiality ≤0.005mm. The surface hardness is HRC55-58, and the hardness after chrome plating is HV1000 (HRC62);

5-Uses: It is suitable for the surface matting and calendering of various plastic plates, sheets, films, leather, paper and other products such as PMMA, PC, PET, PP, PT, PE, ABS, PVC and so on.

|

Decai Steel Roller and Rolls Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing

|

|

Material

|

45# steel with plating,stainless steel

|

|

Hardness

|

50-70 degree

|

|

Tolerance

|

0.2mm

|

|

Types

|

Mirror roll, chrome plated, anilox roll |

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

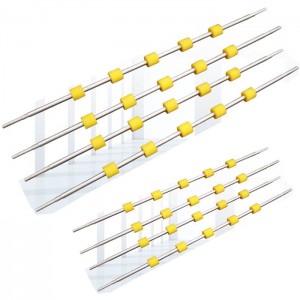

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|