-

-

DC-2158 Heat Transfer Printing Machine for Plastic PP/PE Bucket pail

Heat transfer printing is a popular method of printing on plastic PP/PE materials. The heat transfer printing machine uses heat and pressure to transfer printed designs onto the plastic surface. This process is widely used in the packaging industry, as it provides high-quality and durable printing that enhances the visual appeal of the products. -

Heat transfer film roll flower design pet heat transfer film printer for plastic box

Heat transfer film for lunch boxes is a type of plastic material that is designed to be applied onto the surface of lunch boxes using a heat press machine. This film is available in different colors, patterns, and designs, and it can be customized according to the user’s preferences.

The main function of heat transfer film for lunch boxes is to protect the exterior of the lunch box from scratches, stains, and other damages, while also adding a decorative touch to it. The film is made from high-quality materials that are safe for food contact, so it does not pose any health risks to the user. -

High quality PET Printed Heat Transfer Foil/Film Laser Sticker for Plastic

PET Printed Heat Transfer Foil is a fantastic new product in the world of printing and design. This material is made from high-quality PET film, and it is specially designed for heat transfer applications.

One of the most exciting things about PET Printed Heat Transfer Foil is its versatility. It can be used on a variety of different surfaces, including plastics, and even glass. This makes it an ideal choice for all sorts of projects, from creating custom t-shirts and tote bags to designing one-of-a-kind home decor items. -

UV Resistance Heat Transfer Printing Film for Plastic Paint Bucket

As the demand for plastic paint buckets continues to grow, it is important to invest in high-quality heat transfer printing film to ensure a durable and appealing finished product. Heat transfer printing is a popular method for decorating plastic containers as it offers excellent adhesion and scratch resistance. -

IML in mold labeling film static generator IML static charger

An electrostatic generator is a device that generates electrical energy through the principles of electrostatics. It does not use moving parts or traditional power sources such as batteries or fossil fuels, making it a clean and sustainable source of energy. -

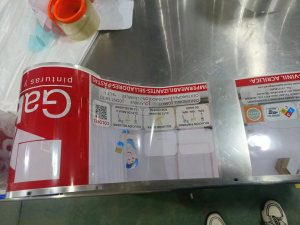

Iml in mould labels for plastic big table

Iml in mould labels for plastic big table is a piece of plastic paper or other material attached to an object or container with information about the product it contains, its purpose, its contents, its price, or other attributes. Labels are used to provide essential information about the product being sold or transported and are often required by law for safety or regulatory reasons. They may also be used to brand or market a product. -

Hologram Rainbow Transfer Printing Hot Stamping Foil Film

Hologram Rainbow Transfer Printing Hot Stamping Foil Film is a special type of decorative film that is widely used in printing industries. The hologram rainbow effect creates a stunning visual impact on the product by adding bright and vibrant colors to it.

-

Decai Eco-friendly heat transfer film thermal transfer label sticker with good quality

Heat transfer film is a decorative material used for plastic product decoration, it can provide customized services, customized according to customer requirements. -

Metallic IML in mold label for plastic lunch box

Product description IML in-mold label is a decorative material used for plastic product decoration. It uses OPP/BOPP raw materials. After gravure printing, the pattern and product are combined at the same time as the product is injected to form a decorative effect. IML in-mold labels can be customized according to customer needs, with up to 12 colors, using DIC ink imported from Japan, the color is bright and durable, and it has food and certificates, and infant products can be used with... -

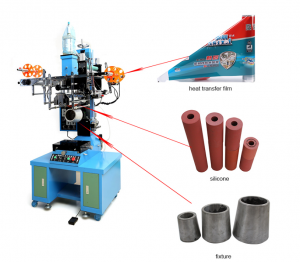

High temperature heat transfer silicone rubber roller for heat transfer printing

Product description The heat transfer rubber roller is specially used in the heat transfer printing industry. It uses silicone raw materials imported from Japan and the United States. It has good high temperature resistance, and the maximum temperature can reach 350°C. The rubber roller is specially added with 2%-3% of silica gel raw material, which is 30% longer than ordinary rubber roller. The heat transfer roller is an important component in various types of printing presses and machines. ... -

Heat Transfer Printing Film For Box Heat Transfer Labeling

The process of using heat transfer film is straightforward. First, you need to create the design you want to transfer onto your cup using a design software or pick one from the pre-made designs. Next, you need to print your design onto the film using a specialized printer. Once the printing is complete, you cut the design out and transfer it onto your cup using a heat press.

FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Decai's bronzing, heat transfer silica gel roller and wheel, hot stamping silicone rubber plate(pad)are widely used in stationery, electrical appliances, toys, cosmetics boxes, cigarette packets, wine box wood, stainless steel, glass, paper, leather, soft and hard plastic printing packaging field.