FREE SHIPPING ON ALL BUSHNELL PRODUCTS

News

-

The mainly types of heat transfer film

Heat transfer printing is characterized by simple process, few procedures, high efficiency and no pollution. After printing, it has good adhesion, high gloss, clear pictures and texts, accurate color registration, bright colors, safe and non-toxic. There are mainly the...Read more -

What is the reason for the inaccuracy of hot stamping overprinting?

Hot stamping is the most commonly used special process in printing business cards, custom album covers and outer packaging printing, which can make the printed matter dazzling. However, in the actual application process, users will often encounter inaccurate ove...Read more -

Major Advantages Of in Mold Labelings

(1) The label materials are mostly film materials, which are waterproof and moisture-proof, and will not appear blistering, wrinkling, and falling off of ordinary labels. At the same time, the film material does not absorb ink, the pictures and texts are bright, and th...Read more -

Introduction to the classification of hot stamping plate

The hot stamping plate is commonly known as the hot stamping plate or the electric engraving plate, and the zinc plate (with zinc as the plate) and the magnesium plate are generally used. Below, I will tell you about the classification of the bronzing version. ...Read more -

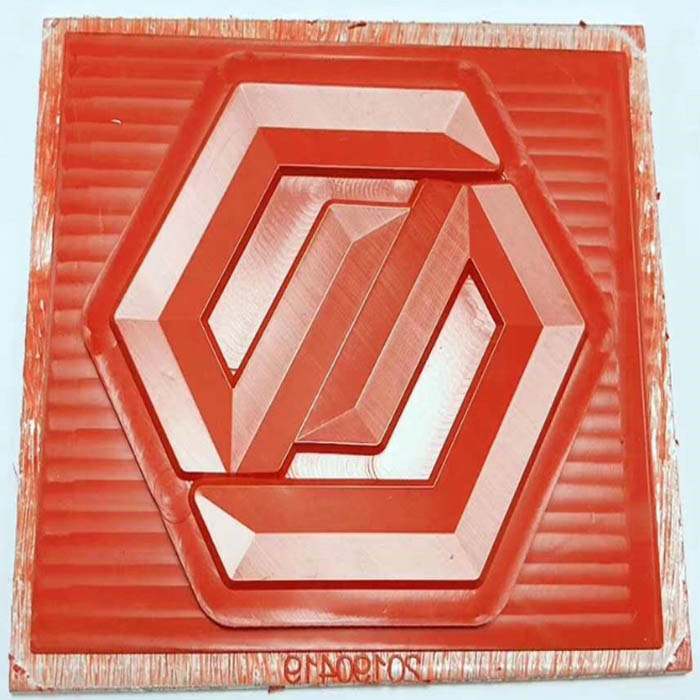

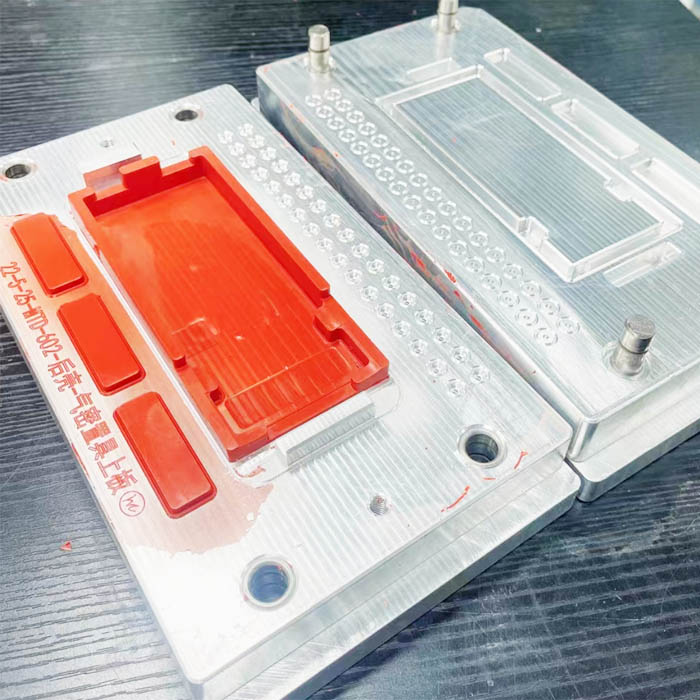

The production method of Stamping Dies Silicone rubber dies

The production method of hot stamping silicone plate 1. Open an aluminum mold, iron mold or copper mold, the kind that can be closed up and down, like a box, clean the mold first. 2. Apply a layer of...Read more -

Advantages of in-mold labeling

Details 1. It directly enhances the anti-counterfeiting function of the product, and can better meet the brand protection needs of high-standard enterprises. 2. The in-mold labeling is exquisitely printed, and can be used for special effects such as laser and aluminum p...Read more -

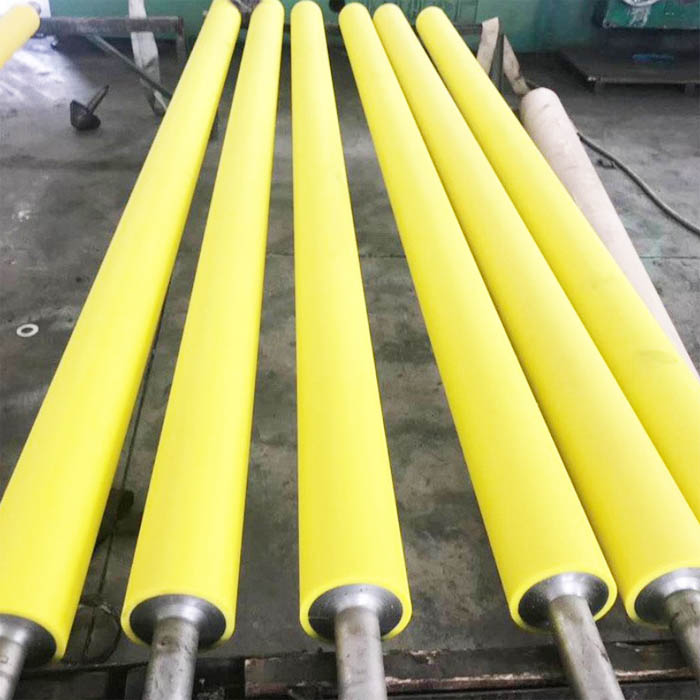

Production steps of rubber rollers

The life of the rubber roller The life span of the rubber roller is not only related to the raw materials used in the production process, but also has a great relationship with the maintenance in daily life. If you do not pay attention to maintenance and maintenance, no ...Read more -

Material selection of rubber rollers

How to choose the material of the rubber roller, today we will share some points 1. Chemical resistance---In order to meet the oil resistance, solvent resistance and chemical resistance, it is more suitab...Read more -

What is hot stamping silicone rubber plate/pad/sheet?

The hot stamping silicone plate transfers the delicate pattern to the product by using the silicone plate as a heat carrier. Hot stamping silicone board/sheet/pad/plate is used for plastic hot stamping. It plays the role of heat transfer. There are two types of hot stamp...Read more -

The features of heat transfer film

Details A. Material: Transparent PET film. B. Accurate chromatography, good adhesion, high gloss, clear graphics; c. Production time: Normal flm can be finished within 8-1 Odays. The metallic and glitter(laser) film finished within10-12days. Because it needs more days f...Read more -

What’s the in mold label?

In-mold labeling refer to pre-printed paper, synthetic or thin-coated labels with a special hot-melt adhesive on the back, which is placed inside the model before plastic blowing, injection molding to create a plastic bottle or basin. The label and the container form a whole, the label and the bo...Read more -

Coated Roller Silicone Rubber Roller For Heat Transfer Bucket Machine

a. Silicone Rubber Roller is ideal for transferring decorative cylindrical and large flat or curved surfaces. Its exclusive formula of silicone has first-class softness and elasticity, can easily match the different surfaces of plastic parts, and has high heat resistance, easy to polish the sha...Read more