In-mold labeling, or IML, is an increasingly popular way for manufacturers to add custom designs and branding to their plastic products. By incorporating the label directly into the mold during the manufacturing process, IML is able to provide a more durable, seamless, and professional look than traditional labeling methods. With customized IML labels, businesses can create a unique and recognizable brand identity for their products, while also conveying important information to consumers.

One of the advantages of IML labels is their versatility. They can be used on a wide range of plastic products, from food packaging and household containers to automotive parts and electronics. By working with a reputable IML label supplier, businesses can choose from a variety of materials, sizes, shapes, and colors to create a label that is perfectly suited to their needs. Whether it's a small logo or a detailed product description, IML labels can incorporate any design or text that a business requires.

Another advantage of customized IML labels is their ability to withstand harsh conditions. Unlike traditional labels that can peel, smudge, or wear off over time, IML labels are highly resistant to water, heat, abrasion, and chemicals. This makes them ideal for products that will be exposed to the elements, stored in industrial settings, or handled frequently.Additionally, because IML labels are integrated directly into the product, there is no risk of them falling off or becoming damaged during transport or use.

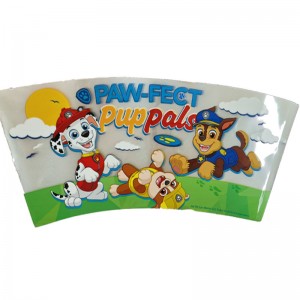

In addition to being practical and functional, customized IML labels can also enhance the aesthetic appeal of a product. With the use of high-quality graphics and vibrant colors, businesses can create eye-catching designs that capture the attention of consumers. This can have a positive impact on sales and brand recognition, particularly in competitive industries where products with visually appealing packaging are more likely to be chosen.

Overall, customized IML labels offer numerous benefits for businesses that manufacture plastic products. From durability and versatility to aesthetic appeal and brand recognition, these labels can provide a cost-effective and reliable solution for labeling and branding needs. By working with a trusted IML label supplier, businesses can create a label that perfectly matches their requirements and helps their products stand out from the competition.